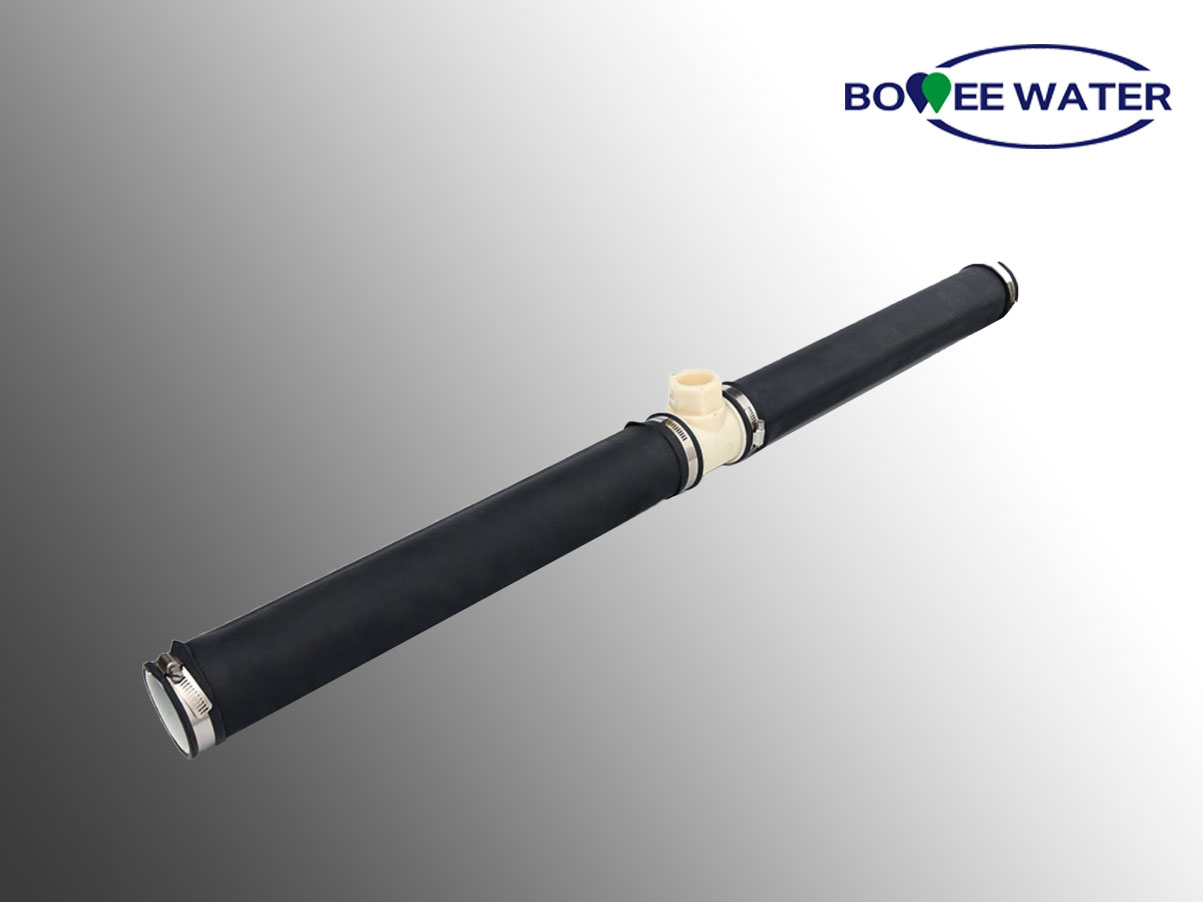

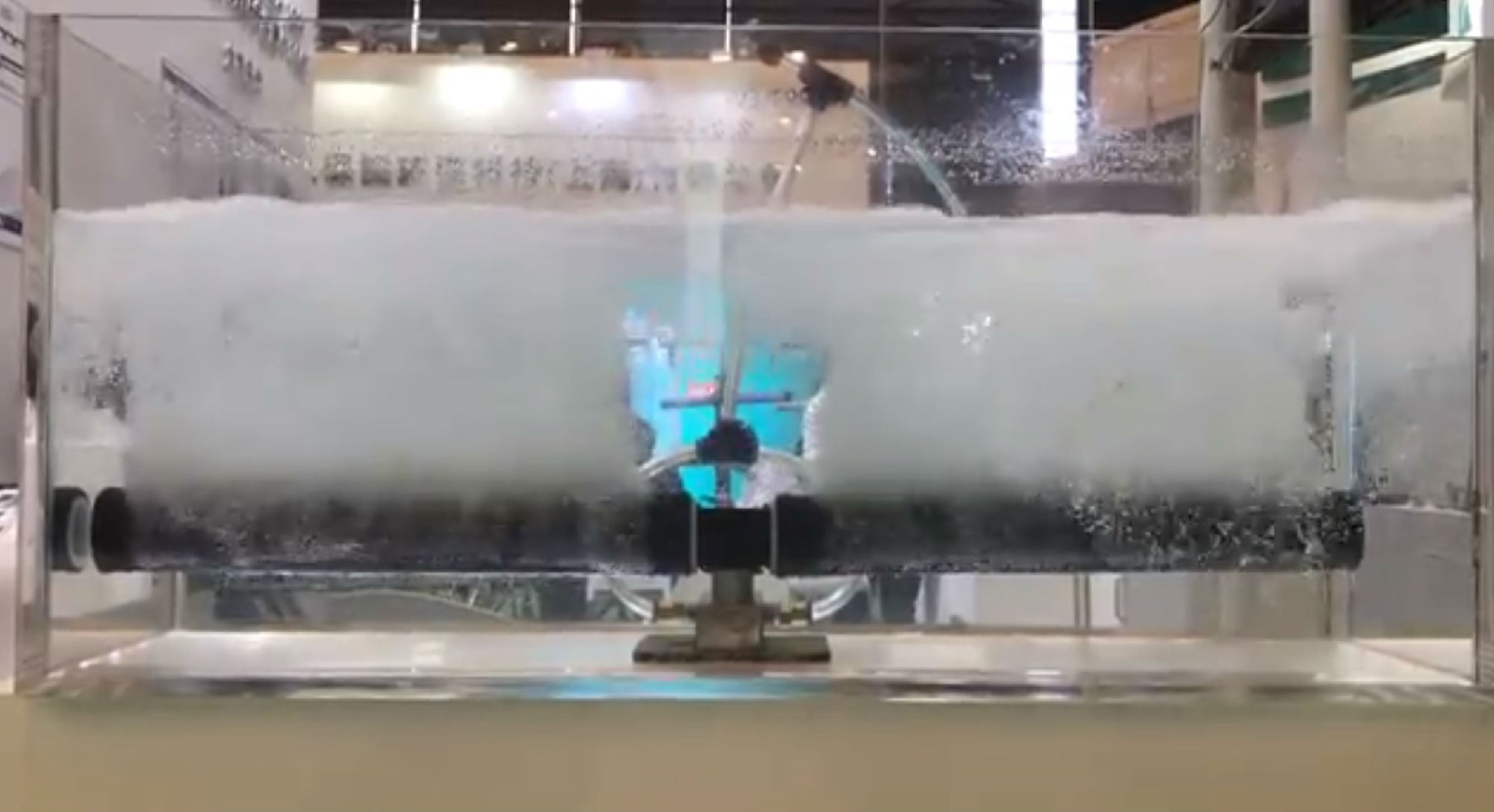

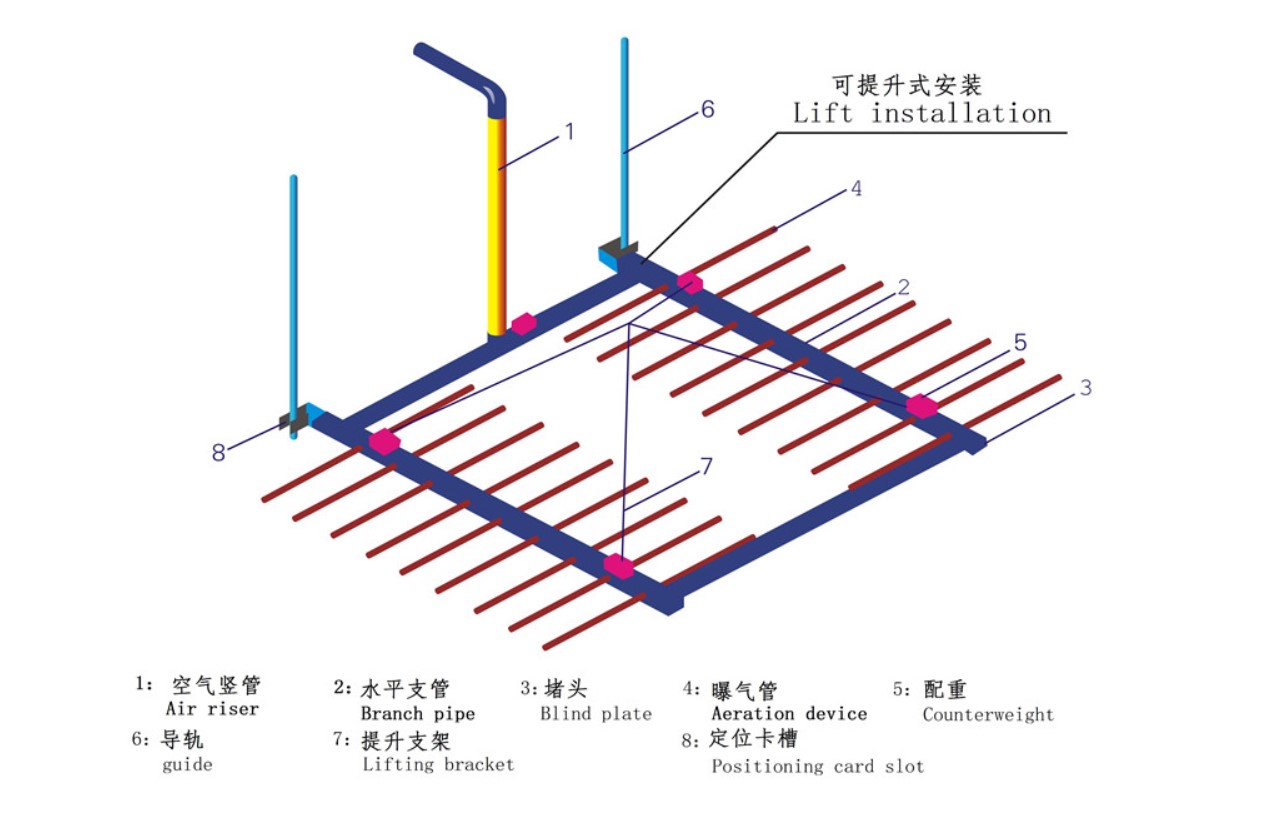

Tube diffuser used in the process of batch and continuous aeration and energy saving design, installation, low cost, high reliability, excellent performance drilling is conducive to efficient oxygen transfer and utilization: to apply aeration system specifications, can use different drilling mode to adjust the working pressure, such as different slot length, distance, the density of drilling.

Specifications:

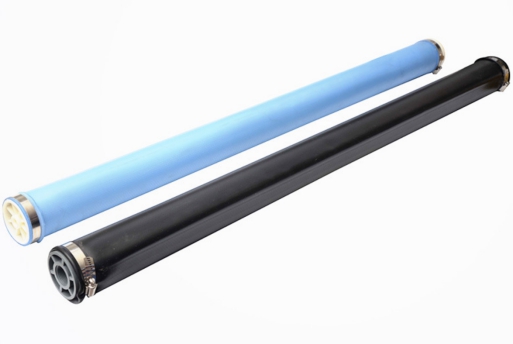

Diameter: 63mm, 93mm,113mm

Length:300-1000mm

Material: EPDM or Silicon

Flow rate:1.7-17m3/hr